ITEMB (InTEgrated Main landing gear Box) Project is part of the Large Passenger Aircraft (LPA) Program area of Clean Sky 2 and it’s linked with “Next Generation Lower Center Fuselage” LPA activities, whose Topic Manager is Airbus.

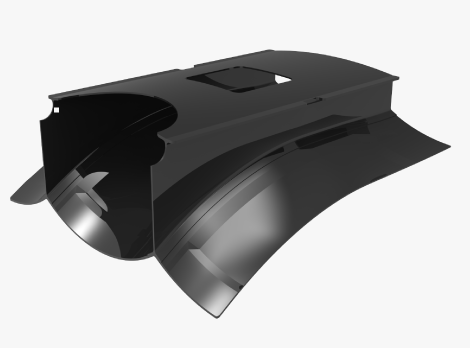

The Next Generation Lower Center activities aim to develop a new generation of Lower Center Fuselage with an innovative concept of Landing Gear fully integrated into the fuselage body.

This concept is considered the next frontier in the development of the Landing Gear System for Medium Range Aircraft family like Airbus A320.

In order to contribute to achieve this goal, the ITEMB Consortium is going to provide a suitable structural configuration of the landing gear bay.

THE PROJECT

Currently, the typical medium range aircraft configuration, like A320, sees the Main Landing Gear integrated under the wing of the aircraft, while the LG bay is made up of several different parts.

ITEMB intends to explore a different scenario, based on an integrated landing system in the aircraft fuselage, concieving a new configuration of the carriage trolley bay where the cart is to be integrated.

The new approach is based on the use of composite materials.

This kind of materials allow a reduction of weight and cost of the structural component. There is only one way to achieve this goal: not following anymore the traditional design paradigms for metals and begin to “think in composite”.

ITEMB’s ambition is, therefore, to create a single composite structure of the carriage bay that reduces assembly costs by optimizing and integrating the entire design, construction and maintenance of the aircraft.

Freezing of the Composite Main Landing Gear Bay

After an initial phase of conceptual studies of different configurations for the upper and vertical bulkhead of the Main Landing Gear Bay, a trade-off between the different parts has been taken, in oder to finalize a suitable configuration to be considered for the next preliminary and detailed design phase of ITEMB.

Different configurations have been compared, in order to achievce the most suitable manufacturing process and loads path, in addiction to weight saving.

The best options has been chosen after some tests, performed on very simple structural components.

Definition of Details & Testing

The concept of the Upper and Vertical Bulkheads of the Landing Gear Bay has been refined, reaching an advanced level of definition.

The chosen detailed concept performed very well during tests, which has been carried on samples of scale models of the composite structural parts, produced specifically to analysis and possible corrective actions, before the realization of the final demonstrator.

During tests it has been possible to find good performances of some of the areas considered most critical, with a consequent reduction in the level of risk, which in perspective provides good guarantees in terms of reliability. The results that emerged in terms of weight reduction are also significant; the cost analysis also highlighted a reduction in assembly costs beyond expectations.

The ITEMB Consortium

ITEMB consortium parties are well balanced and complete each other of competences and expertise.

Project Coordinator for ITEMB, Protom has developed an extensive experience in design & project management. It has developed an extensive know-how in aerospace strictures & system, being able to carry on the entire process from the overall design of a product or sub-assembly to the specific design of detail parts.

Operating in the aeronautical field since 1989, the Company is able to manage all phases of project, industialization, product and assembly of complex aeronautical structures. The core business is mainly represented by large assemblies, as well as metal laminated or machined parts and fible composites manufacturing.

The Department of industrial Engineering – Aerospace Section is an important player in the European Scientific Community. More than eighty years of continuing research and developments have built a solid tradition of excellence based upon a strong relationship between the academic community, the aerospace industry and the research centres.

The ITEMB project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 717190